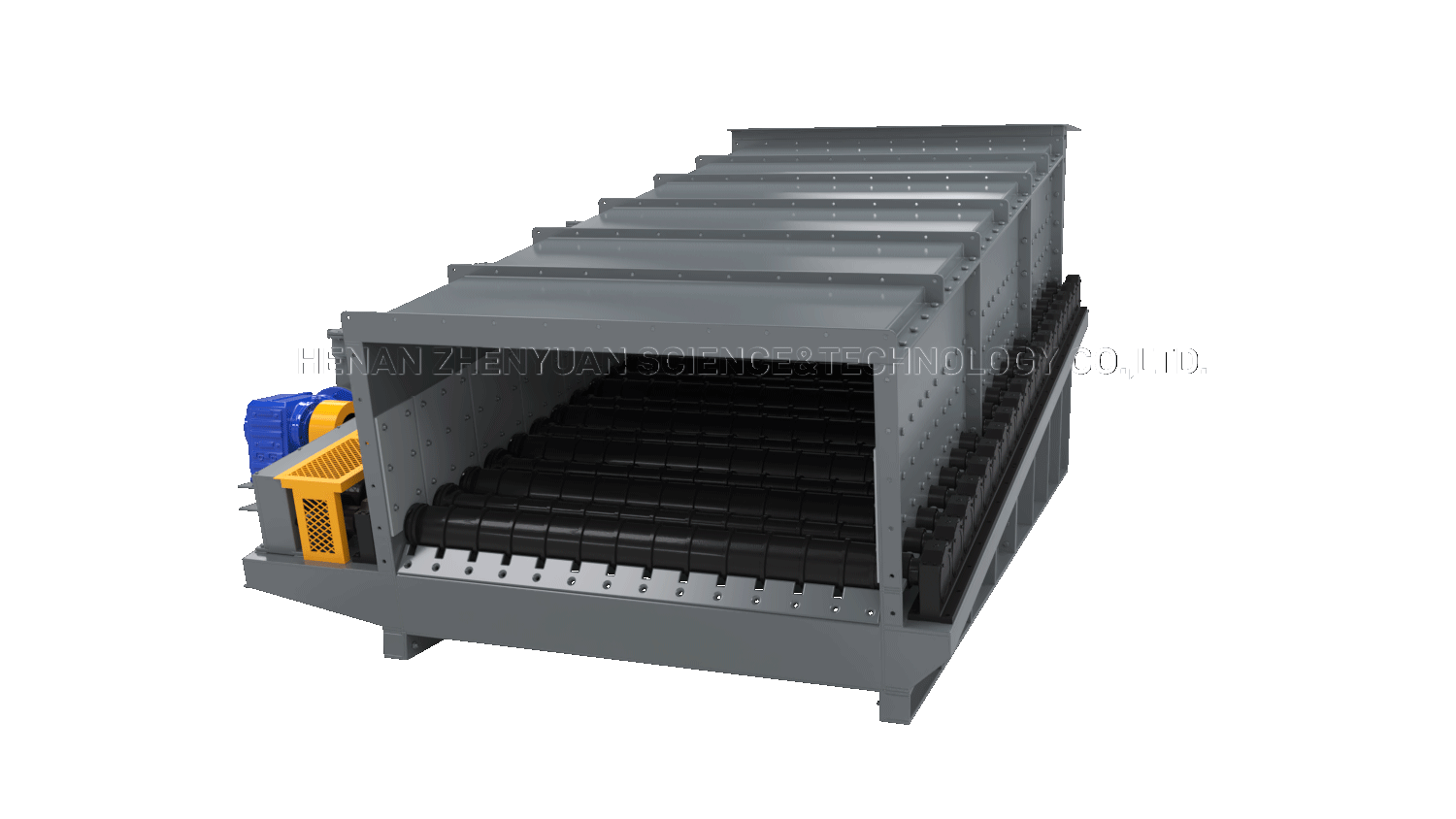

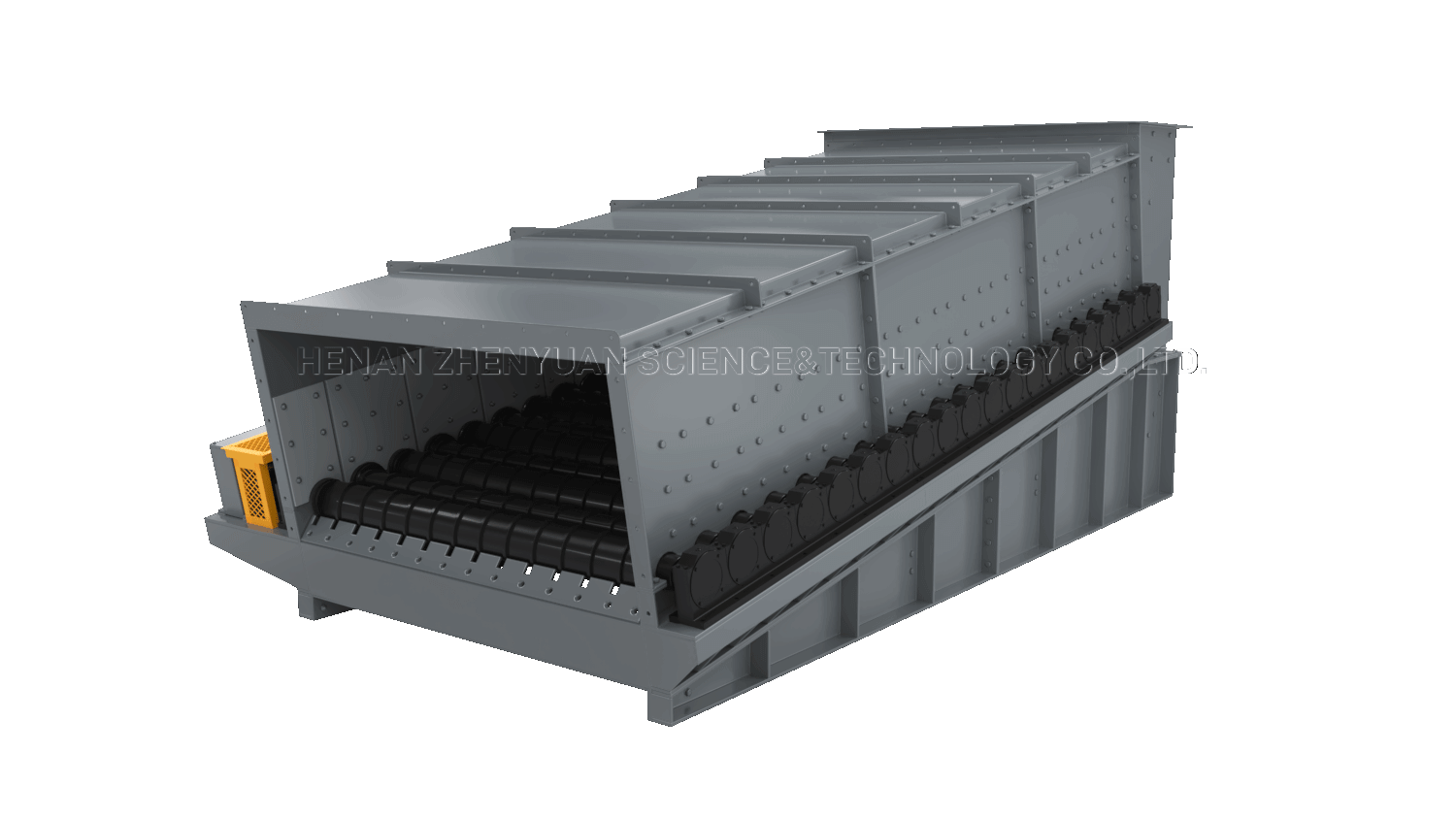

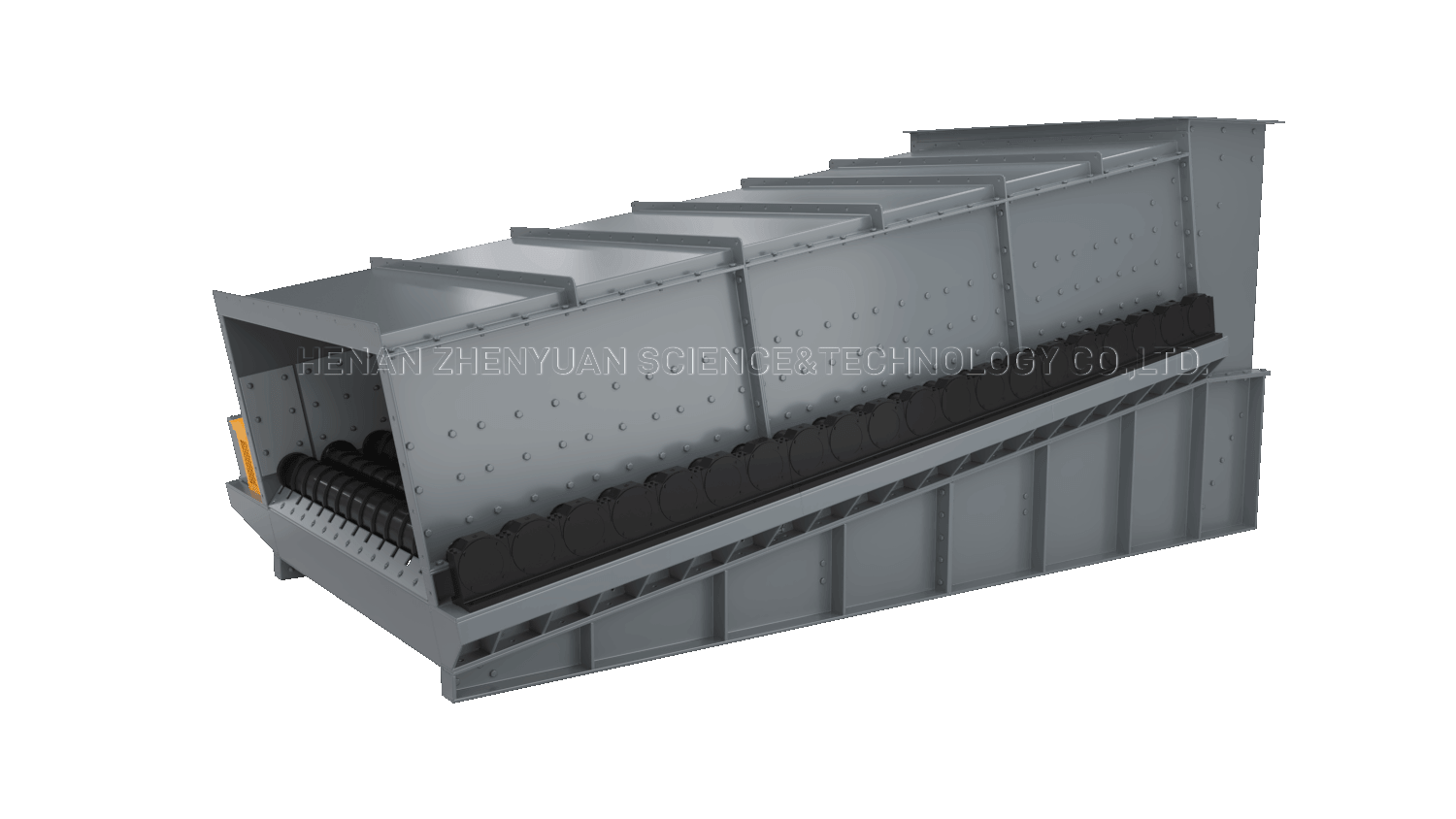

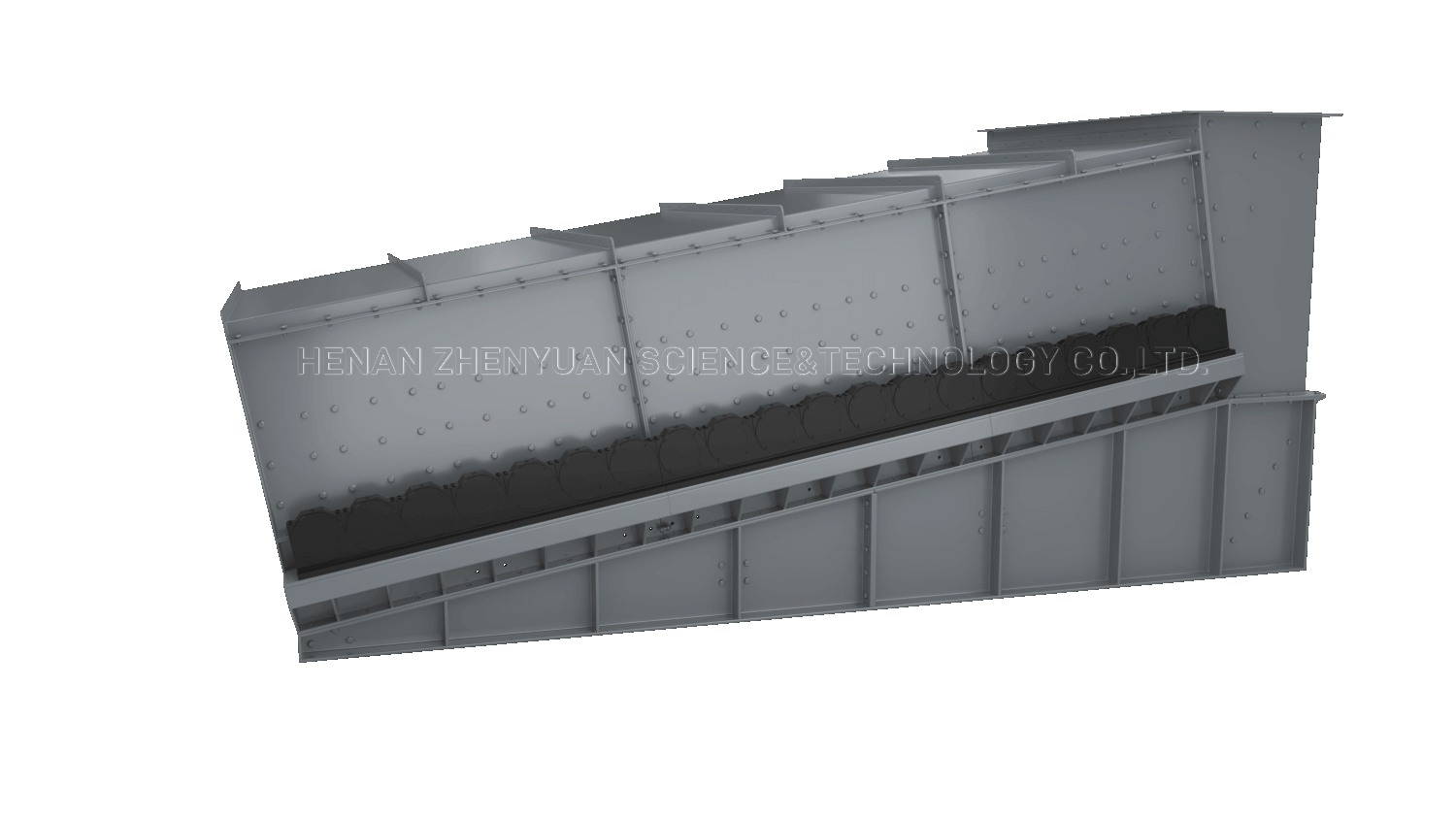

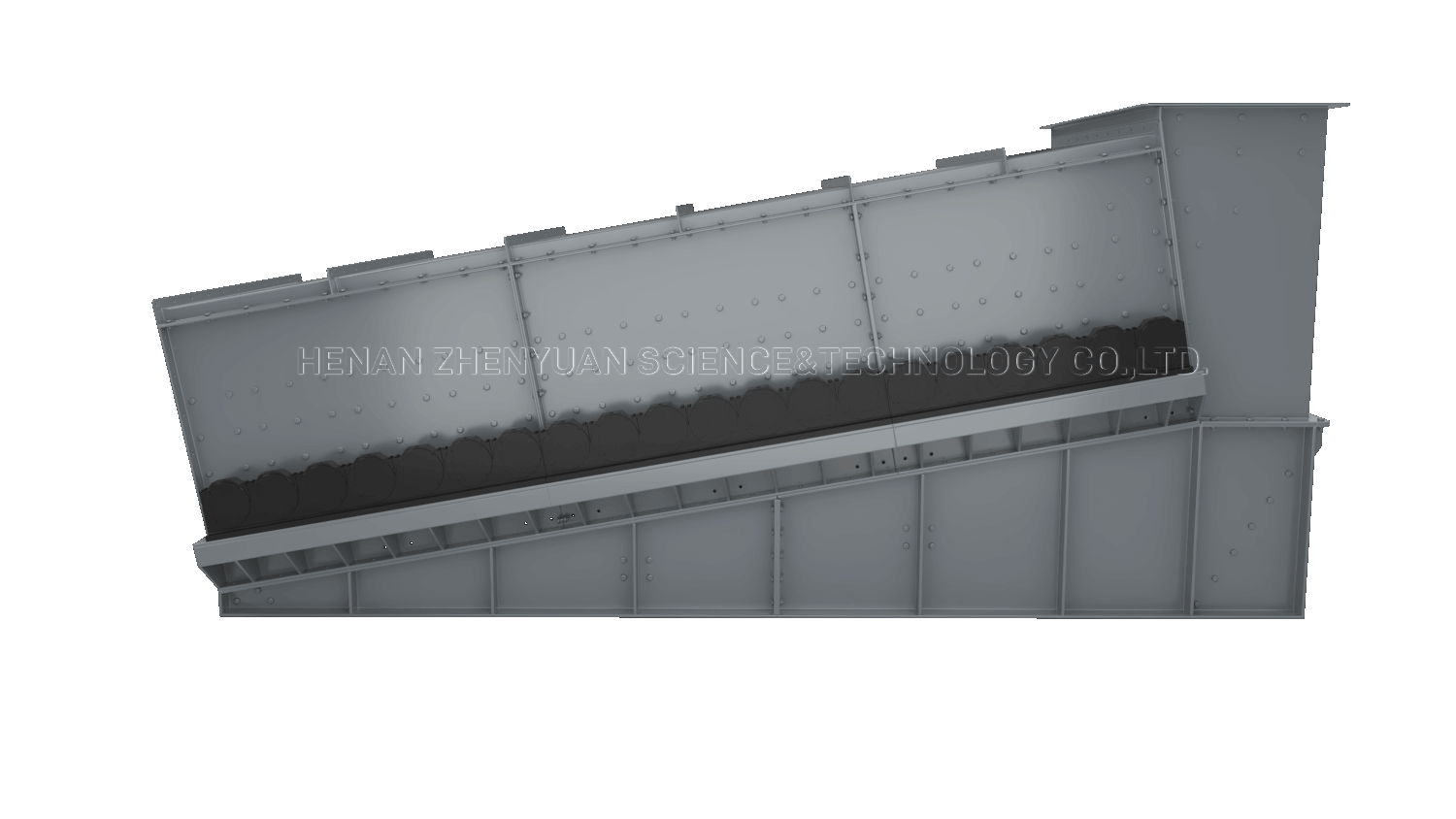

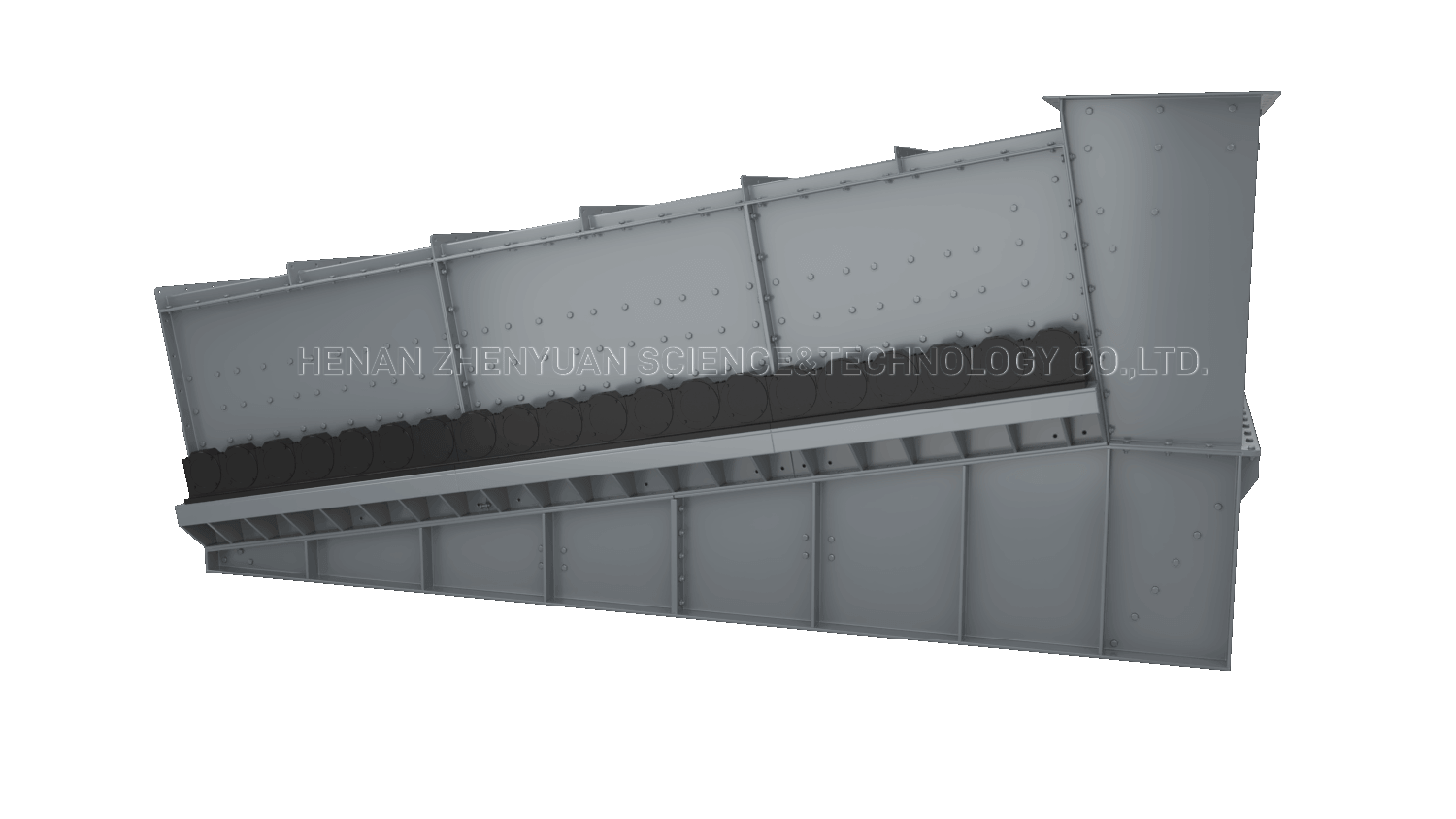

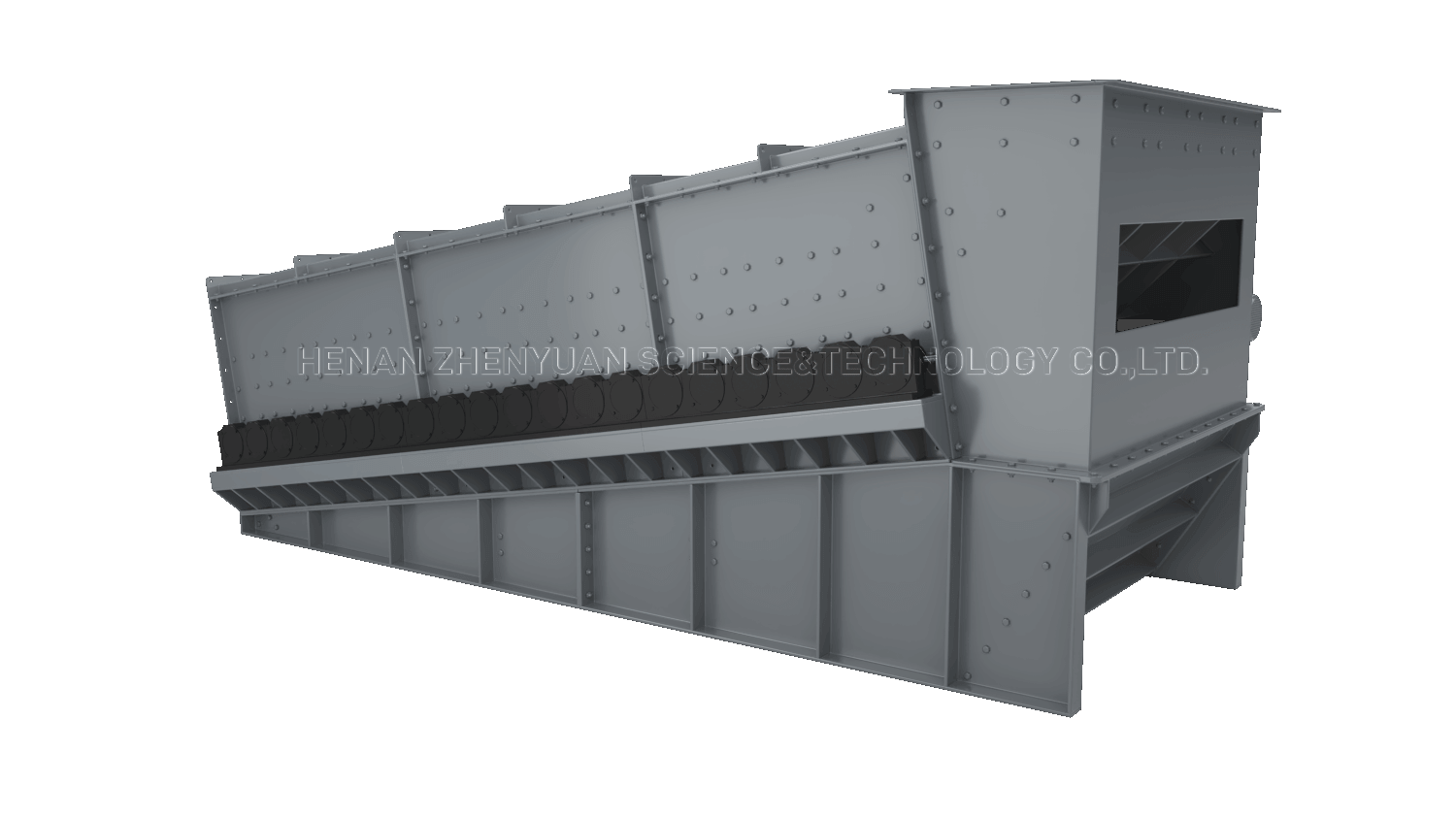

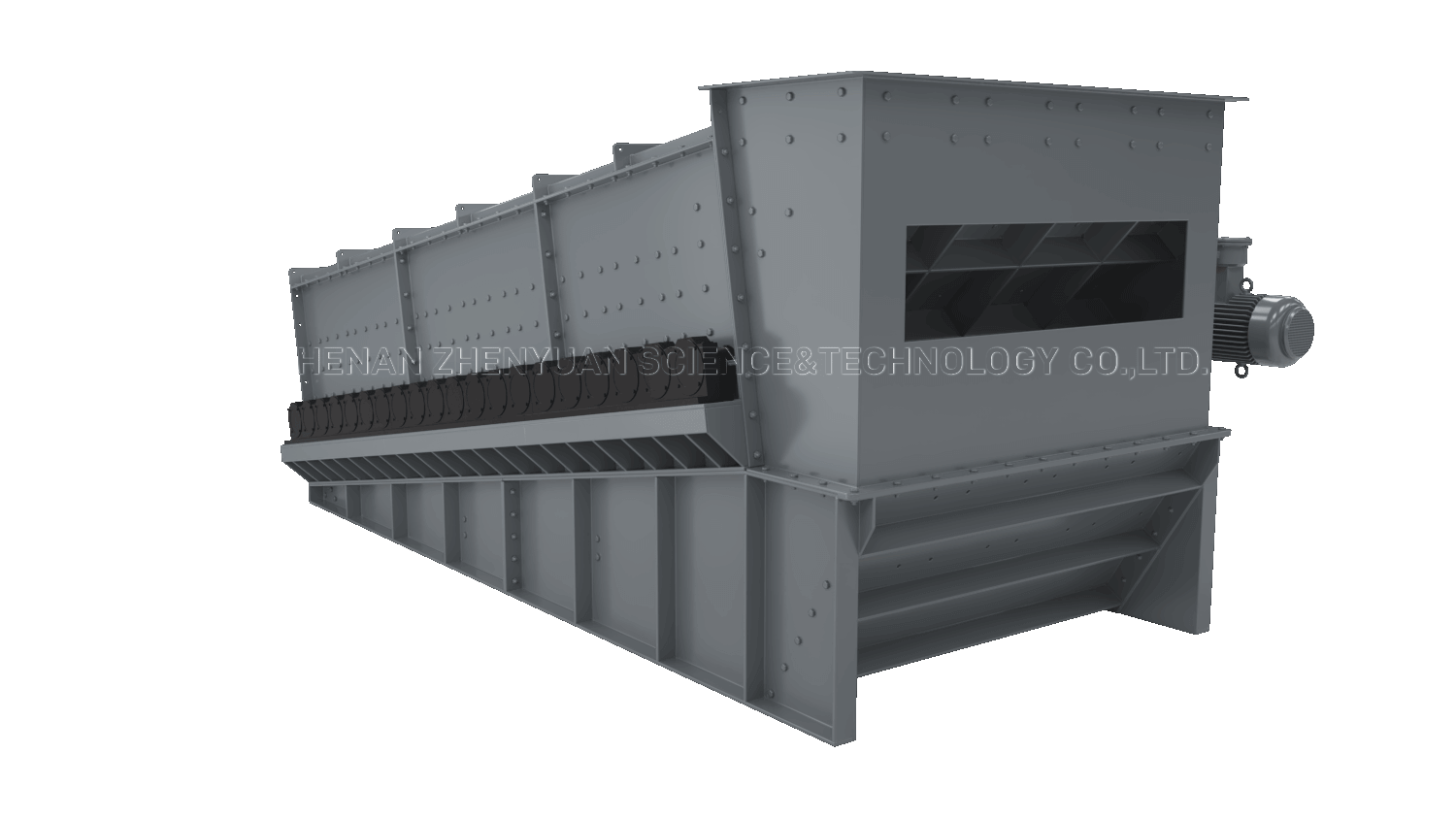

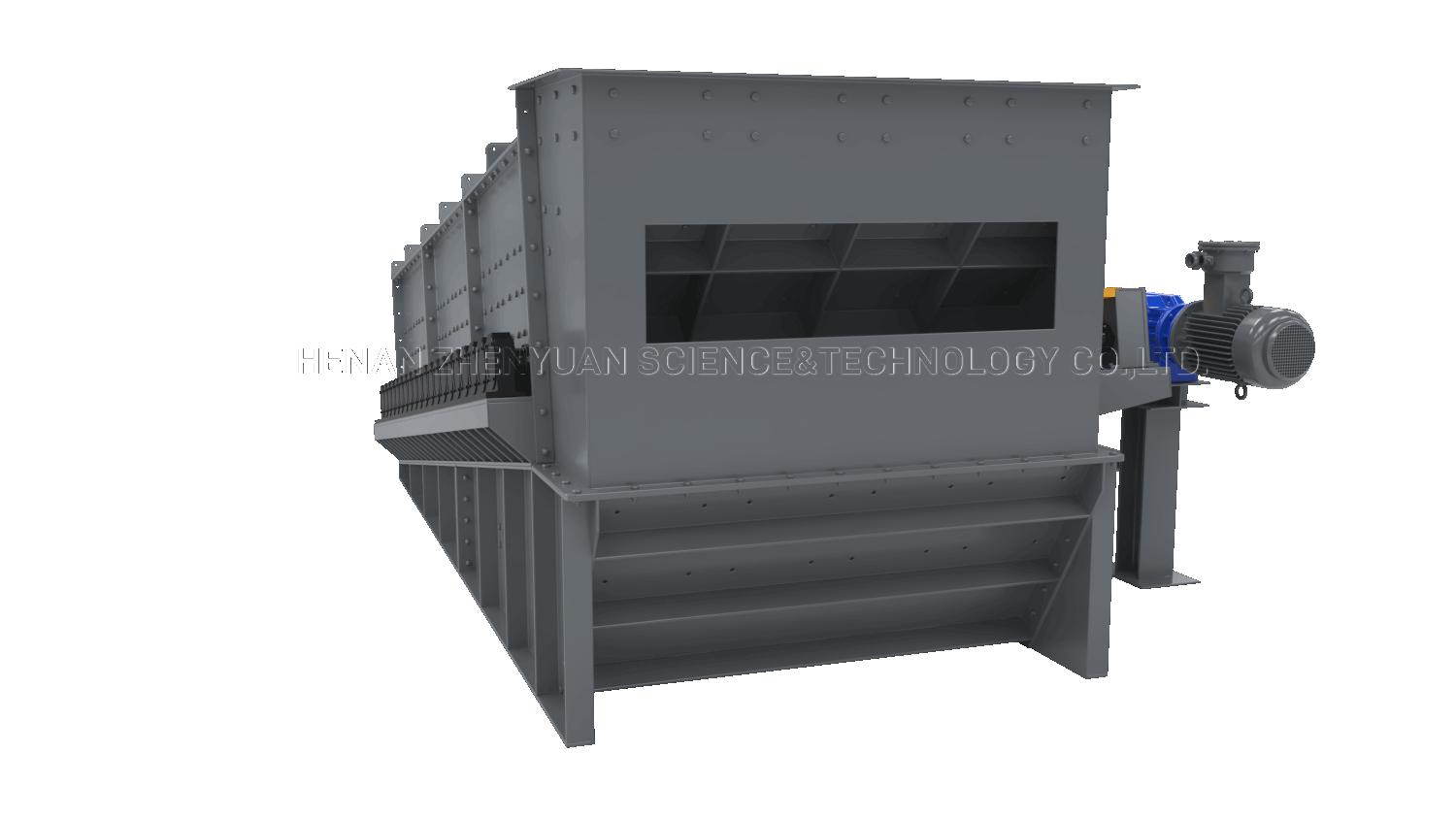

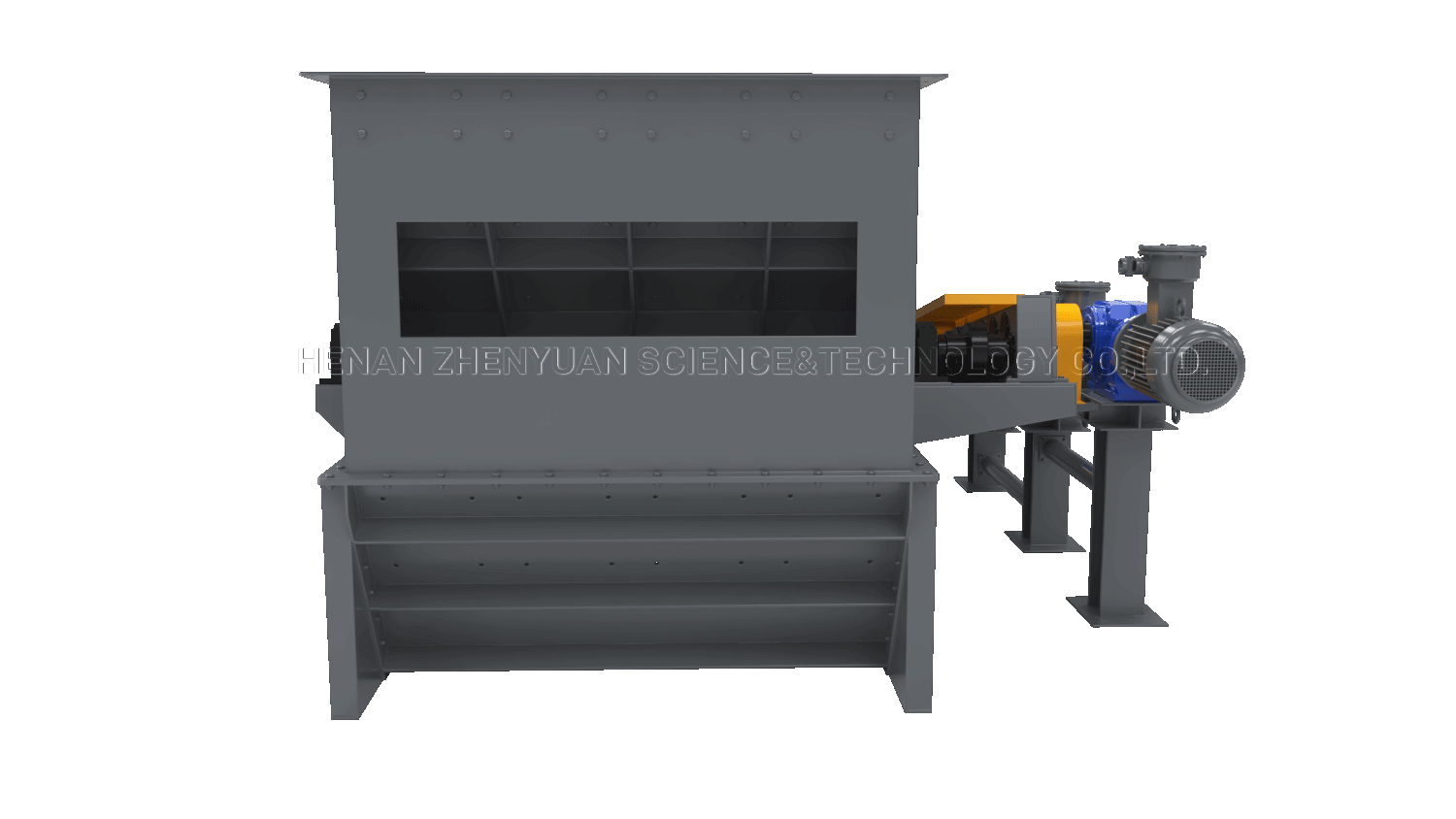

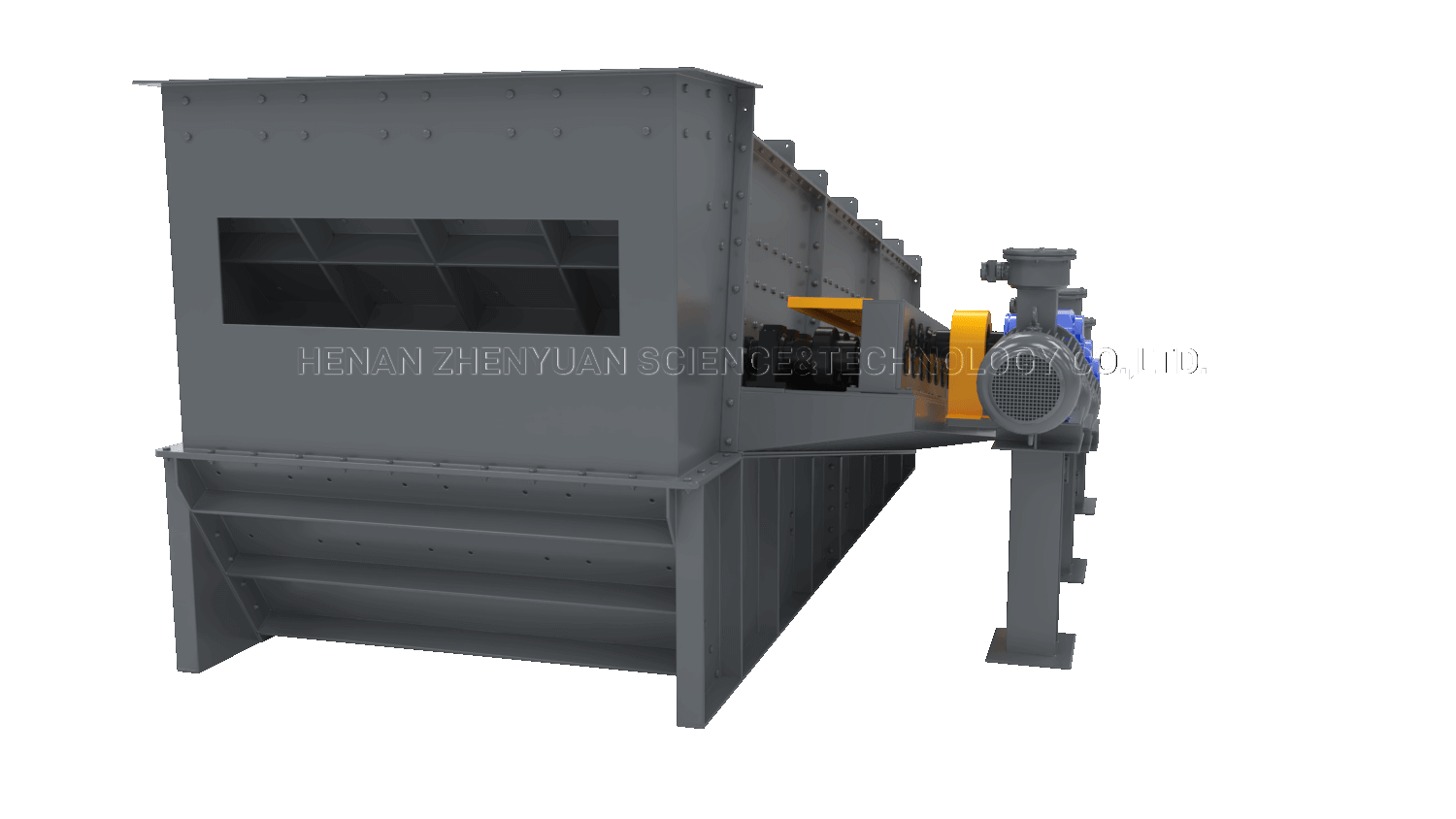

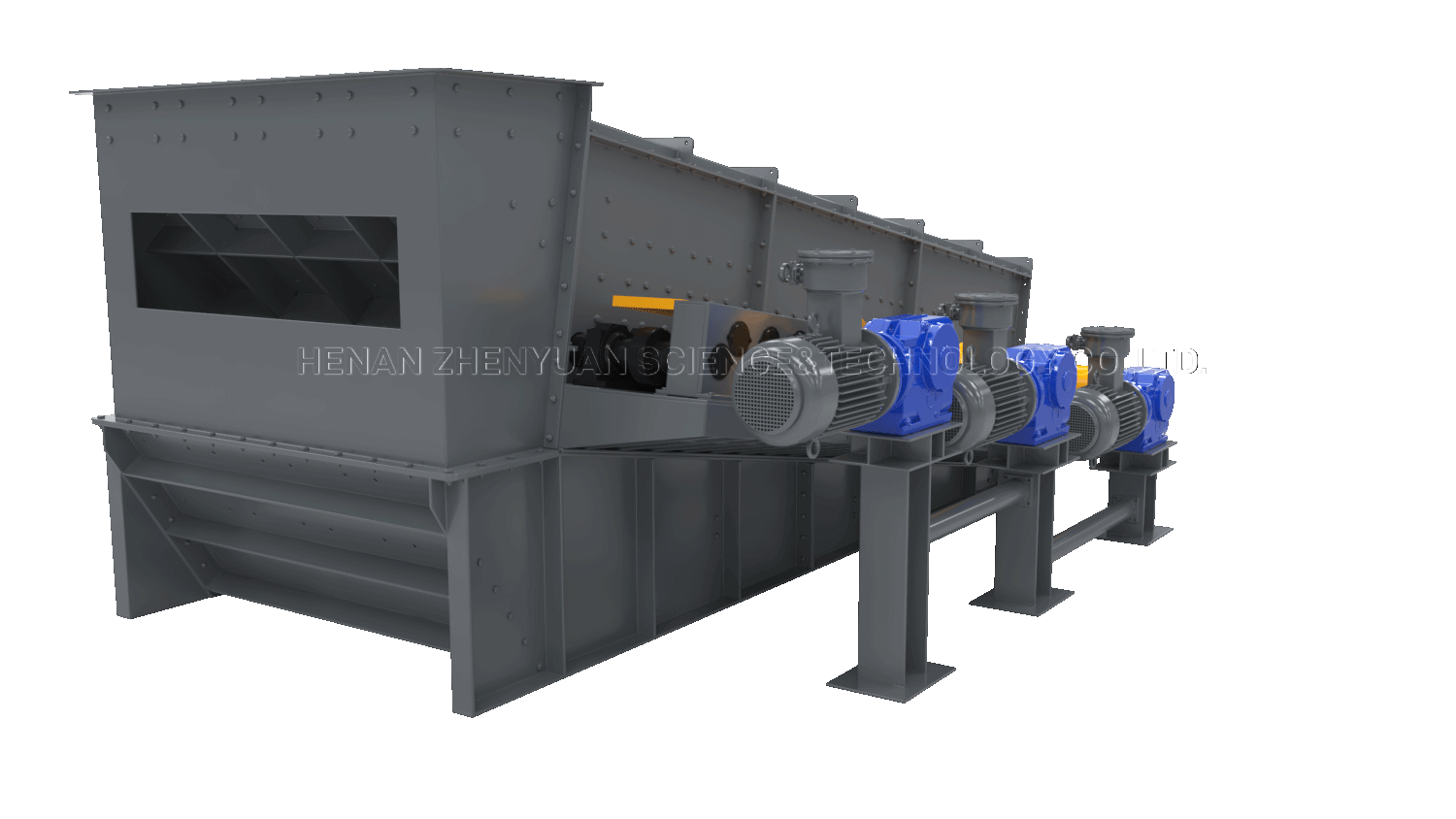

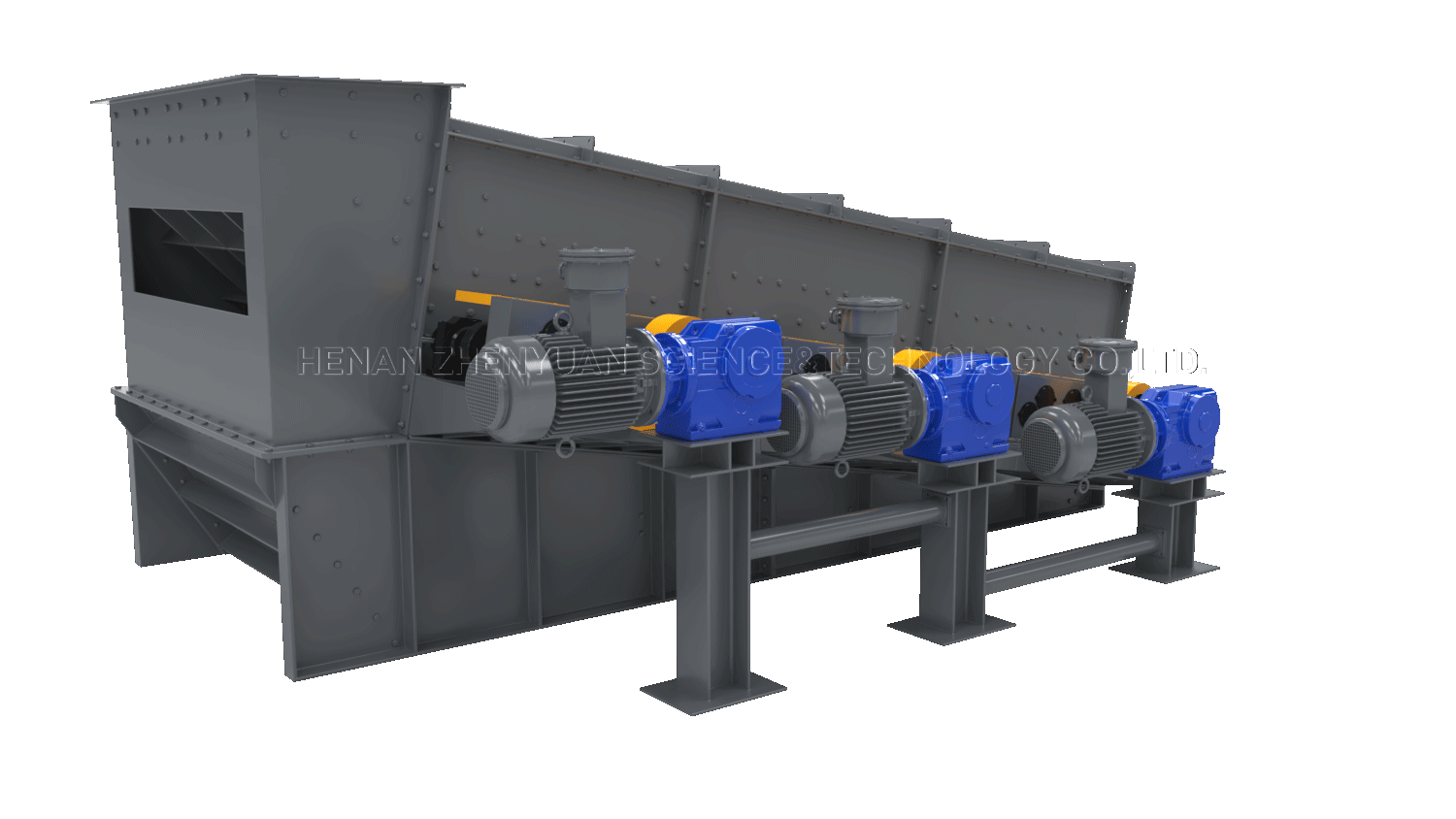

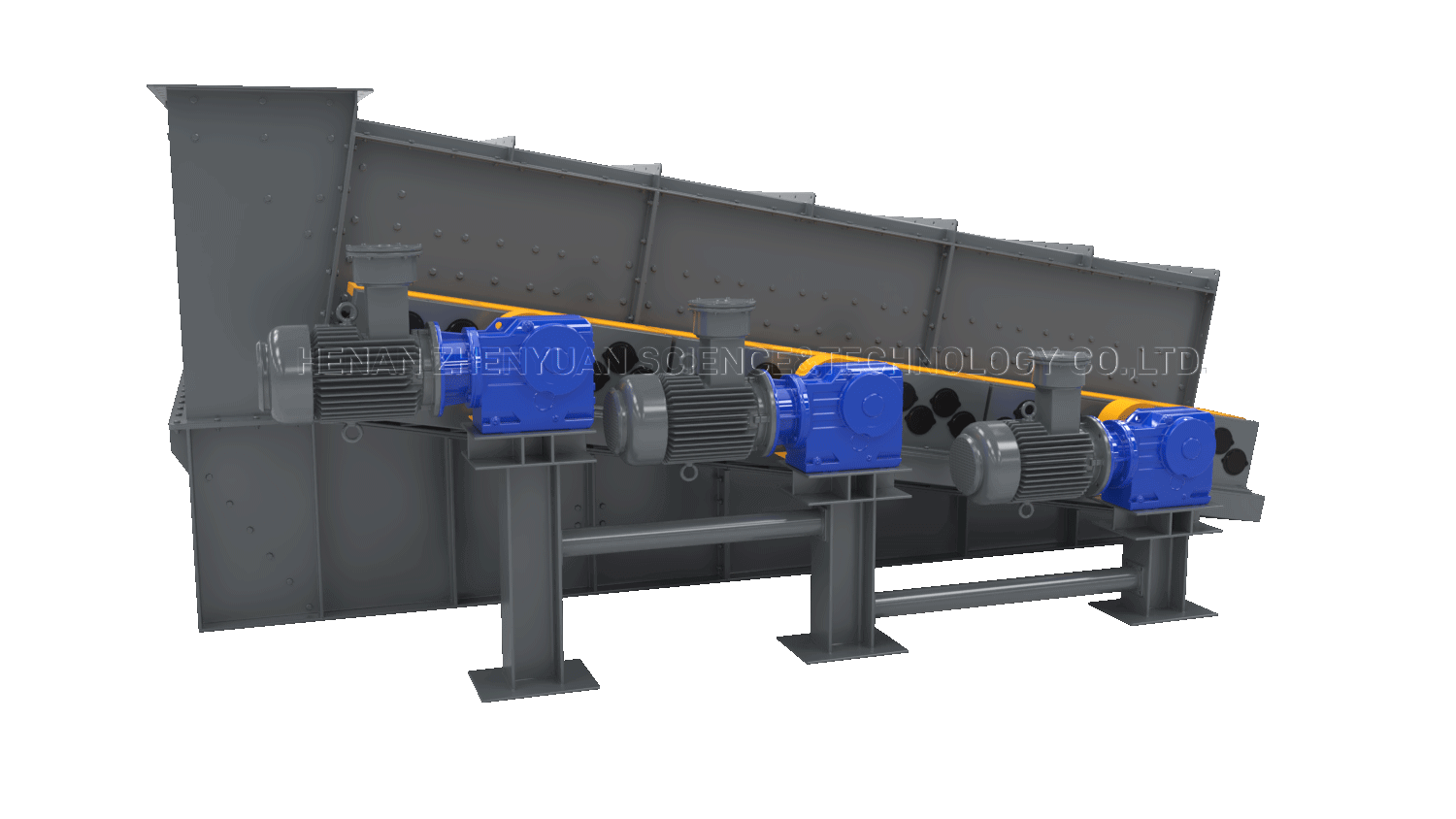

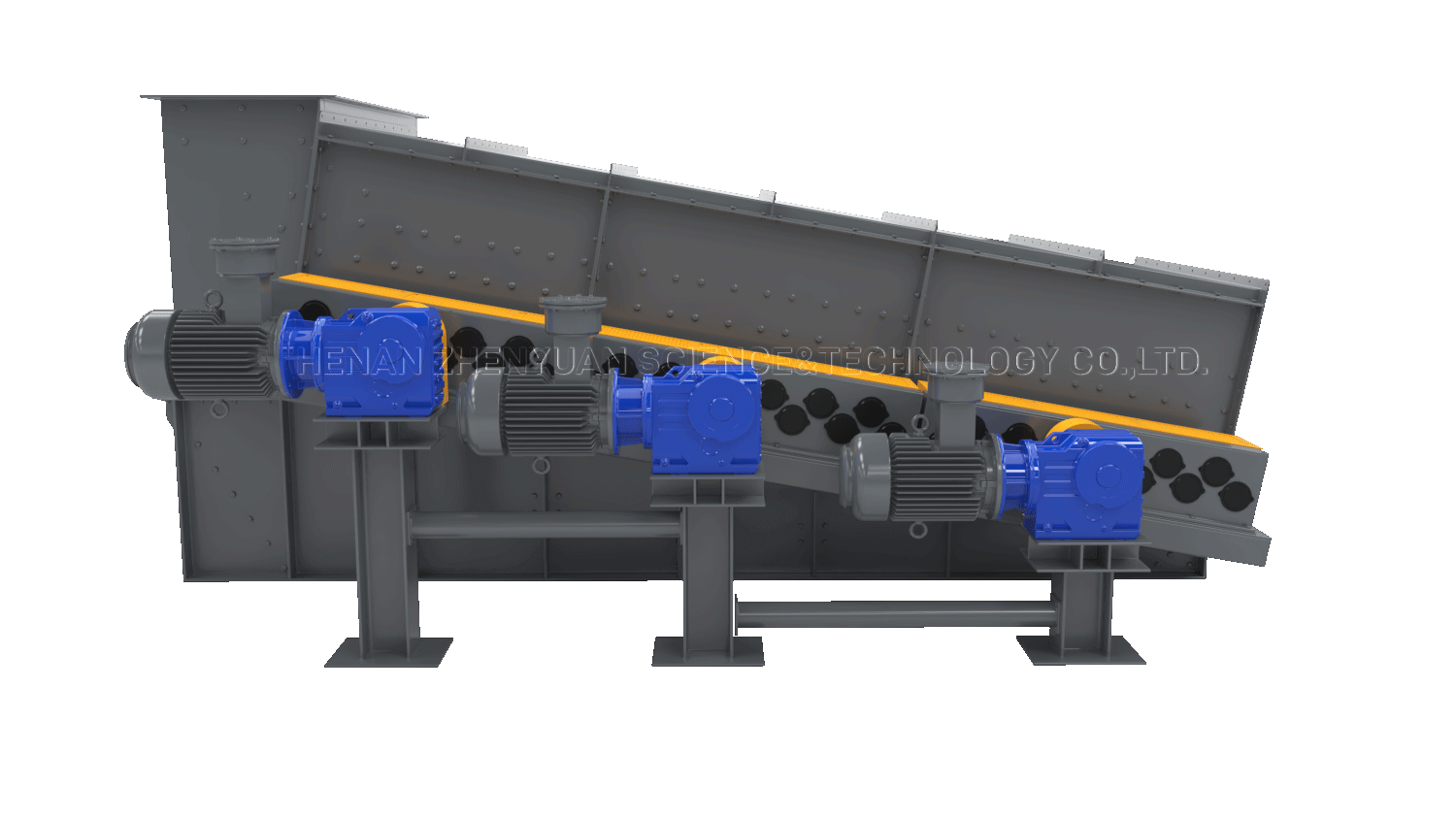

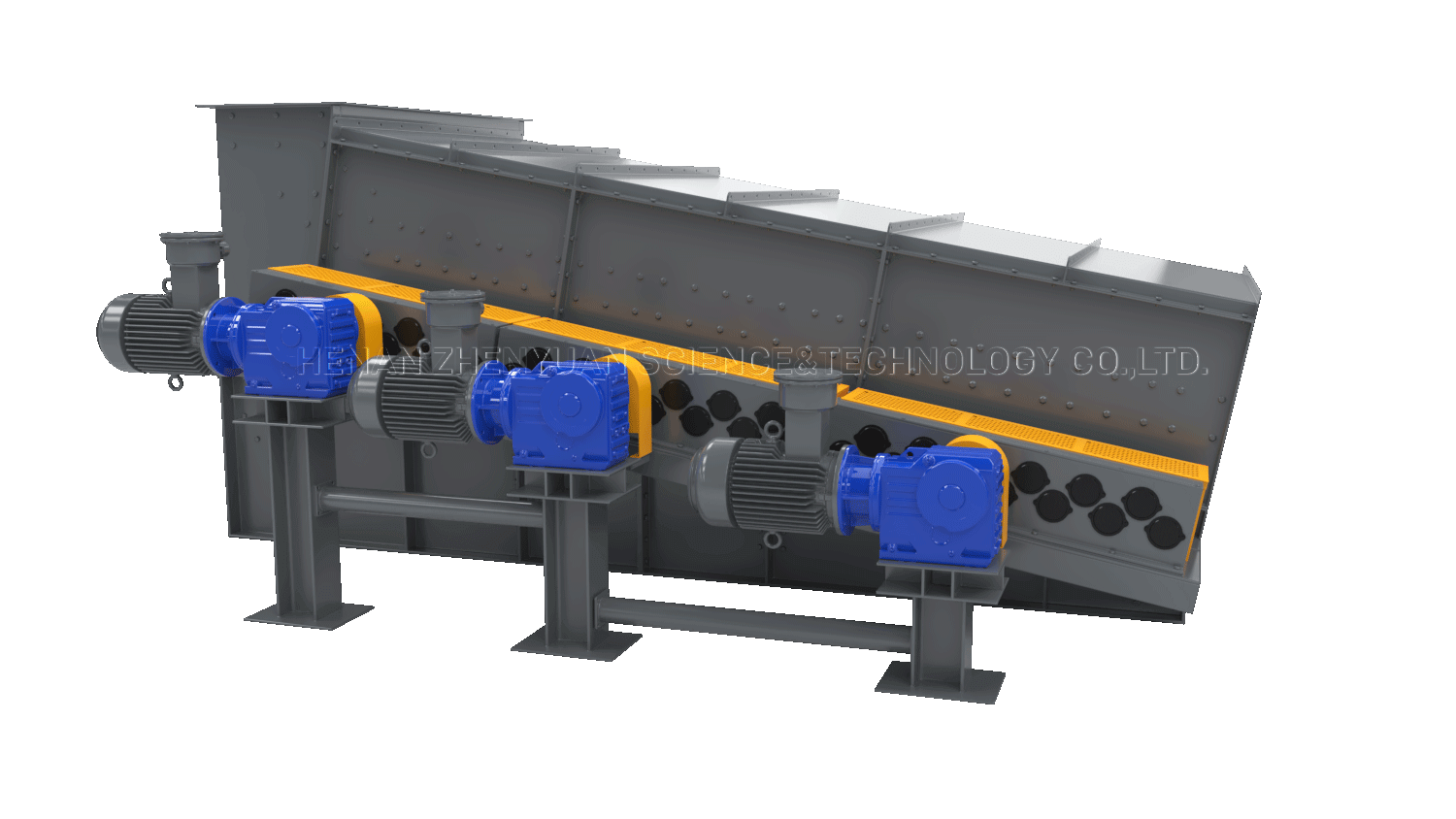

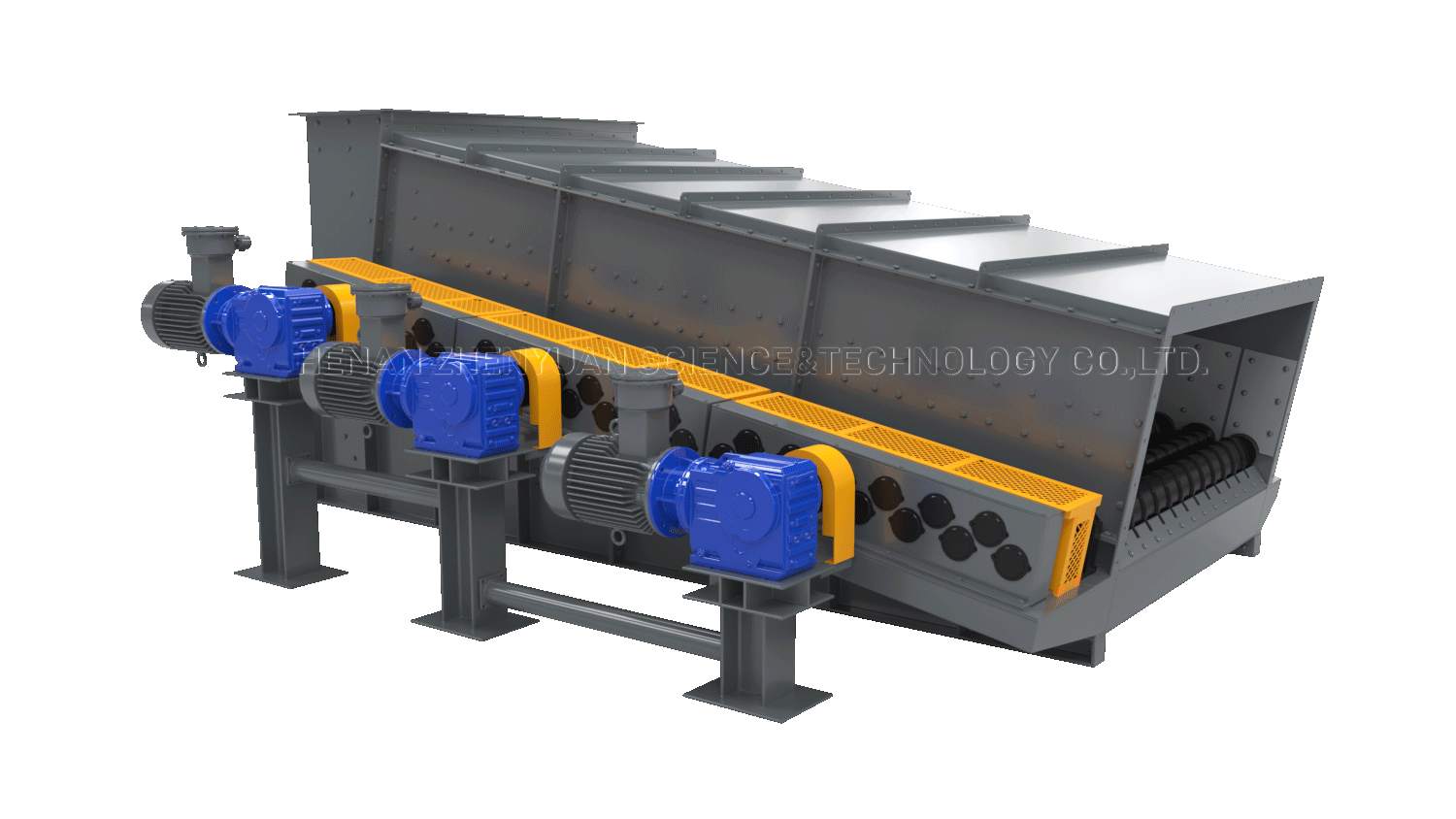

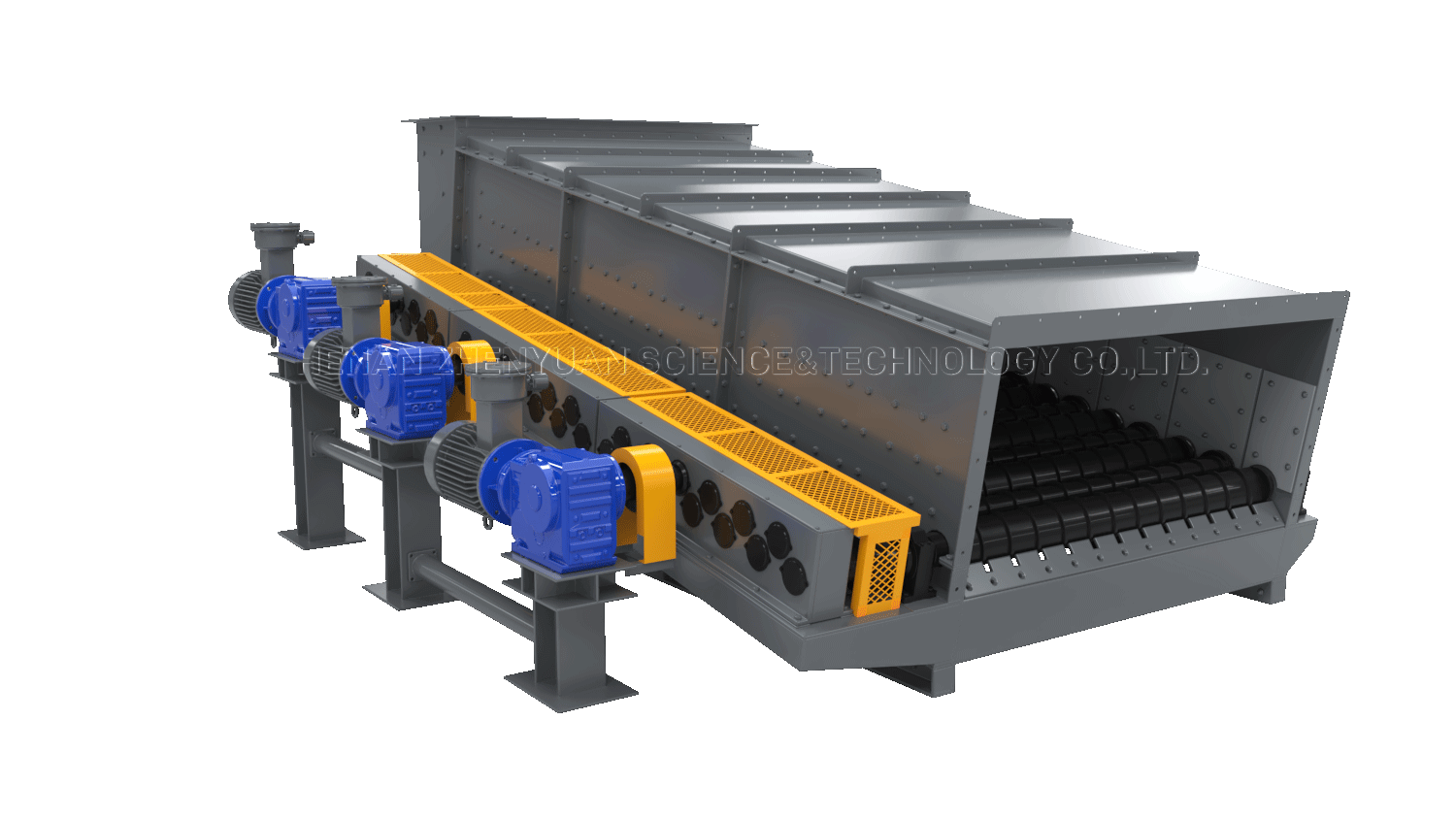

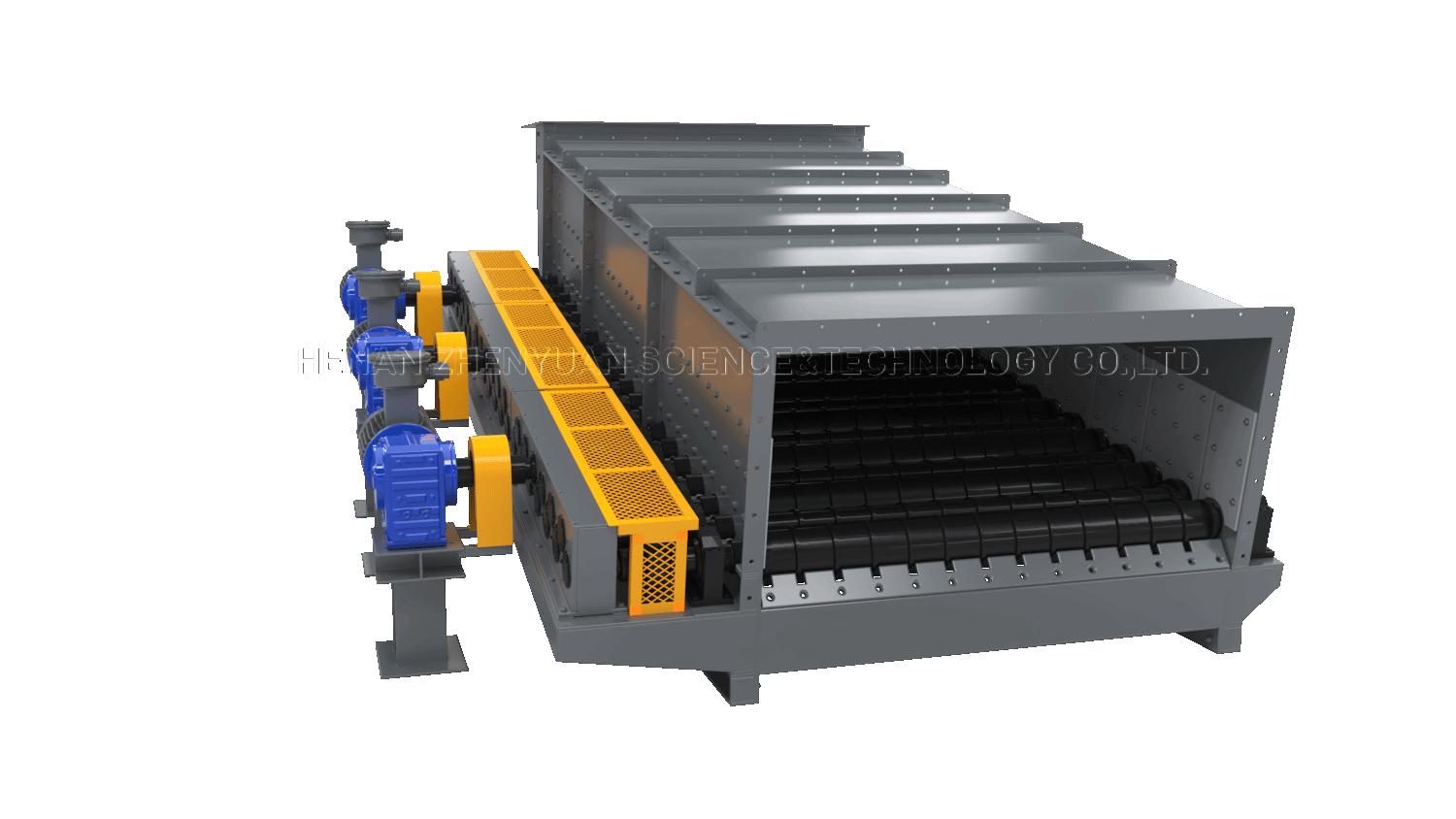

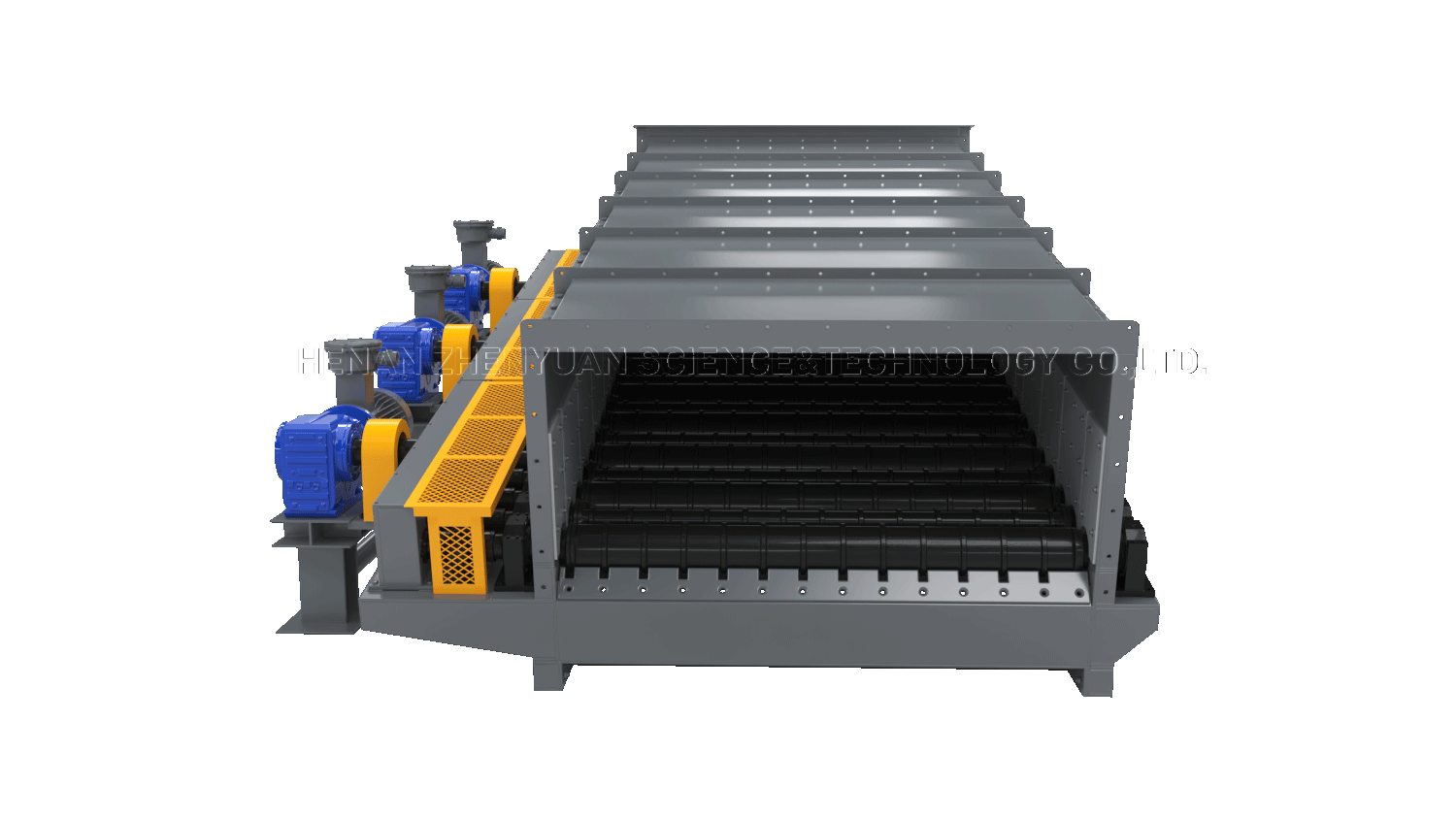

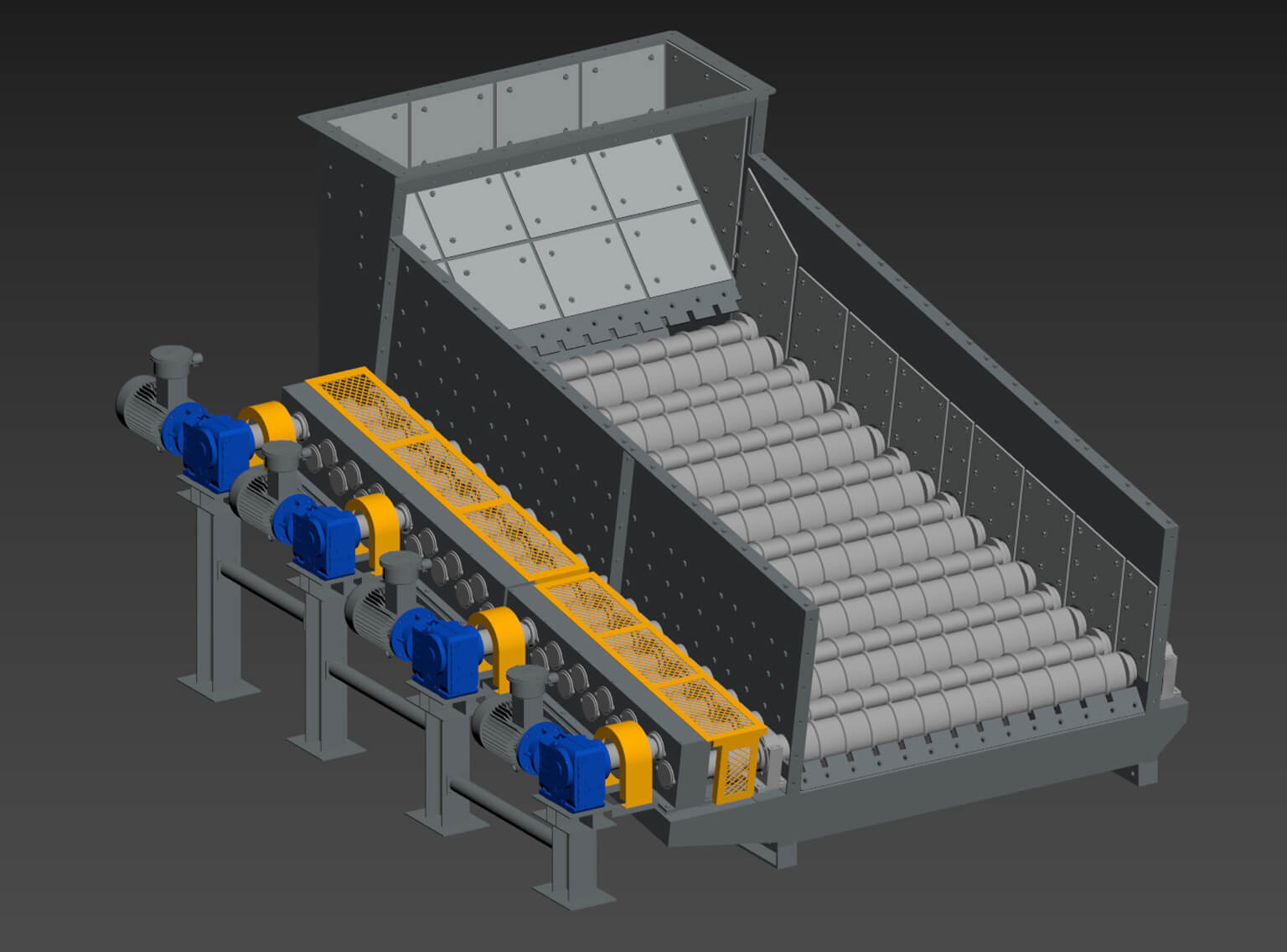

Roller screen surface is composed of multiple parallel roller shafts and staggered screening discs.

Through gear-driven transmission, the rotating blades on the rollers are propelled in the same direction to facilitate material movement. This configuration ensures smooth material flow while achieving rapid stratification of materials. It is widely applied in the mineral sorting processes.

Screen disc adopts large-curvature and small-curvature arc-shaped structures, thereby completely eliminating industry challenges such as roller shaft jamming during the production process.

Submit your details and Talk with one of our technical engineer about your project.

Send Email|

Model |

Screen Width |

Qty of Roller Shaft |

Grading Size |

Capacity |

|

(mm) |

(pcs) |

(mm) |

(t/h) |

|

|

GZS1410 |

1400 |

10 |

10-80 |

400-900 |

|

GZS1612 |

1600 |

12 |

10-80 |

500-1200 |

|

GZS1816 |

1800 |

16 |

10-80 |

800-1600 |

|

GZS2016 |

2000 |

16 |

10-80 |

1100-2000 |

|

GZS2424 |

2400 |

24 |

10-80 |

1500-3000 |

Note: The aforementioned data is for reference only and should not be construed as a natural commitment from the equipment supplier; due to significant variations in rock or ore, the actual production results may differ considerably from the data presented in the table. For specific applications, please contact the Technology Center of Zhenyuan Technology.

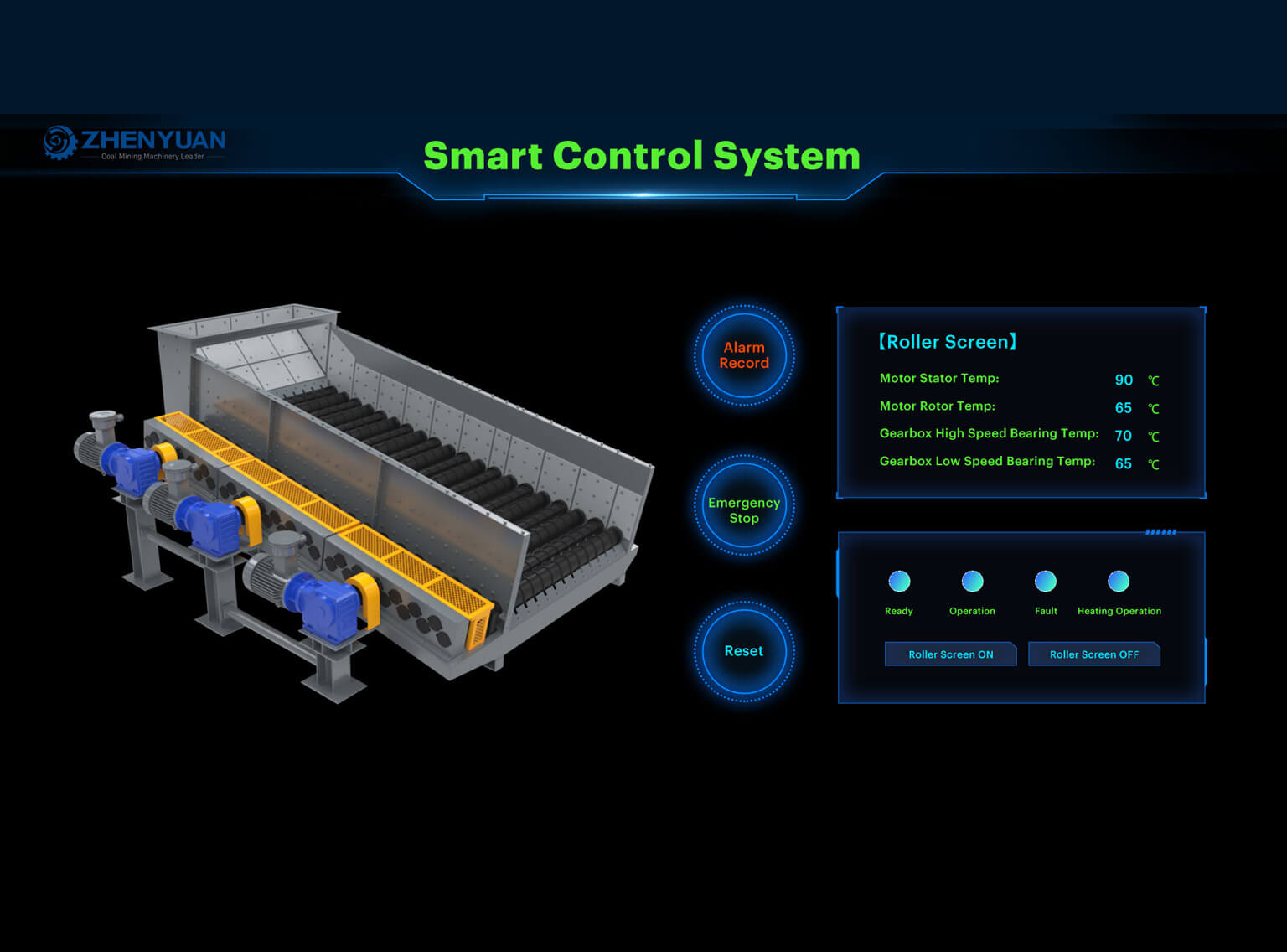

Driving Device

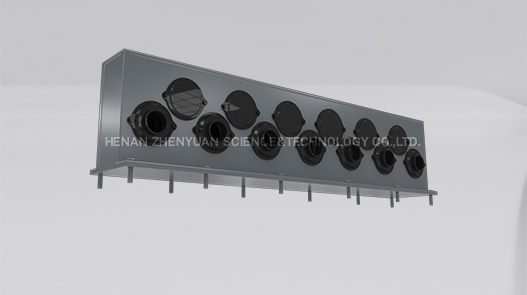

Roller Shaft Assembly

Gear Case